A Chinese research team has found a new way to biodegrade waste plastics

According to Jiangnan University on January 30, Professor Wu Jing's team made progress in the field of waste PET biodegradation, and the research team designed and developed a "bacteria-enzyme" collaborative system with independent intellectual property rights, which can achieve 100% degradation of PET waste plastics. The relevant research results were recently published in the International Journal of Biomacromolecules.

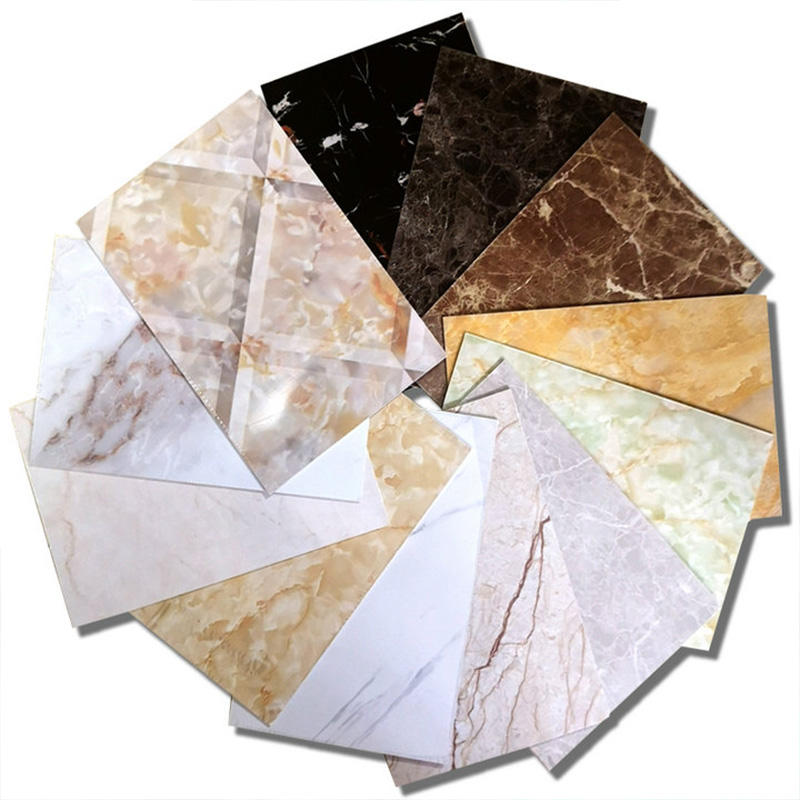

From small straws to large cars, plastic products have been integrated into every aspect of human life. Among them, polyethylene terephthalate (PET) is the most commonly exposed plastic in People's Daily life, widely used in food packaging, textiles, electronics and optical devices and other fields.

Wu Jing introduced that because PET itself has a strong chemical inertia, it takes at least hundreds of years to completely degrade under natural conditions, and a large number of discarded solid PET poses a serious threat to human health and the ecological environment. At present, physical melt regeneration is the main means to achieve waste PET recycling, but due to the large fluctuation of raw material batches and poor stability in the recycling process, the quality of the melt is not ideal. At the same time, the chemical method is to degrade the waste PET by alcoholysis, ammonolysis and other methods, but the chemical degradation process is harsh and the water content of the raw material is strictly controlled.

In response to the above problems, Wu Jing's team proposed the concept of "bacteria-enzyme synergism" through the investigation and experimental design of a large number of literatures, introduced specific microorganisms in the process of enzymatic degradation, and built a new "bacteria-enzyme" collaborative system, which can realize the complete degradation and reuse of waste PET, and eliminate the generation of microplastics and micro-particles.

"Biodegradation technology has the advantages of low energy consumption and environmental friendliness, and has gradually become the safest and most thorough way to deal with PET pollution." On this basis, the recovered monomers can be repolymerized as raw materials to create bio-based plastic products and accelerate the iterative renewal of petroleum-based plastic products." Wu Jing said.