What are the four common types of plastic sheets?

First, polypropylene plastic board, also known as PP plastic board, has high strength and good corrosion resistance, high temperature environment, strong impact resistance. It can be filled, toughened, flame retardant, modified and other processing. This plastic sheet is processed by extrusion, calendering, cooling, cutting and other processes. It has the advantages of uniform thickness, smooth and flat, strong insulation, etc. Can be used in chemical anti-corrosion equipment, ventilation pipes, electrical and electronic and building materials and other fields, the use of temperature up to 100 degrees.

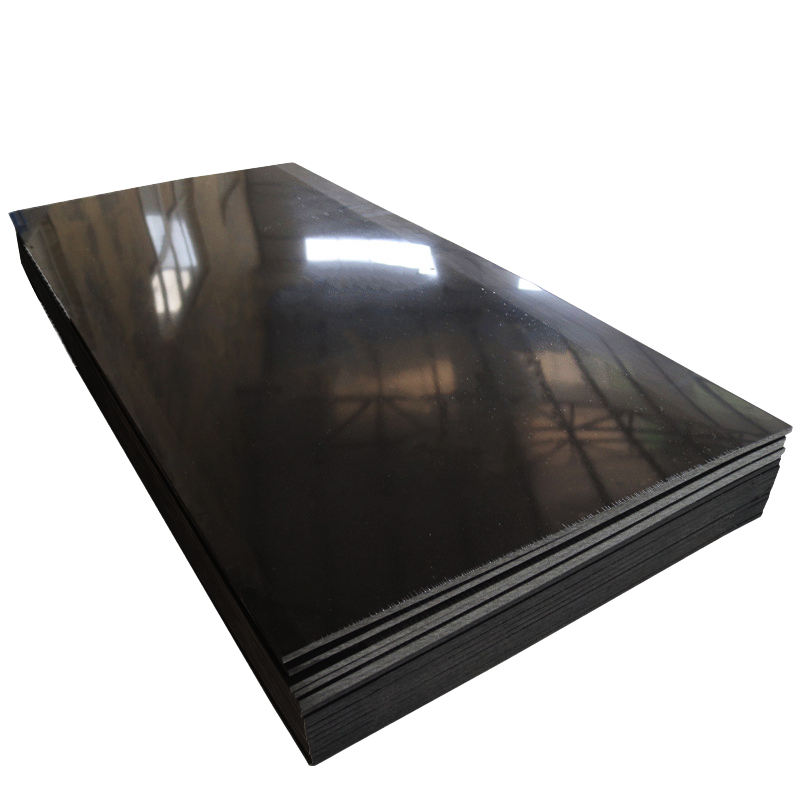

Second, polyethylene plastic board is also called PE plastic board, the raw material color is mostly white, and it can also change its color according to the needs of users, such as red, blue and so on. It has good chemical stability, excellent insulation performance, can resist the erosion of most of the acid and alkali components, low density, good toughness, easy to stretch, easy to weld processing, non-toxic and harmless. Application range: water pipeline, medical device, cutting board, sliding profile and so on.

Third, the color of ABS plastic board is mostly beige and white, high impact strength, good heat resistance, high surface finish, easy to secondary processing. Widely used in home appliances, electronics, packaging, medical equipment and other fields, ABS ginning plate has beautiful and generous characteristics, mainly used in the production of automotive interior and door panels. ABS extruded sheet has beautiful color, good overall performance, good thermoplasticity and high impact strength. Widely used in fireproof board, wall board, chassis board production, can be flame retardant, embossing, grinding and other processing methods.

Hard PVC plastic sheet, also known as polyvinyl chloride hard plastic board, common colors are gray and white, chemical stability, excellent corrosion resistance, high anti-ultraviolet ability and easy to process, working range from minus 15 degrees Celsius to 70 degrees Celsius are used, is a very superior thermoforming material. It can even replace stainless steel and other corrosion-resistant synthetic materials. It has been used in petrochemical, pharmaceutical electronics, communication and advertising industries. The following is an introduction to the physical properties of PVC plastic board. In fact, the new material plastic metal composite plate performance is better.